Key Characteristics

- Designed to ASME PCC-2, ASME VIII, and ASME B16.5

- Enables safe bolt replacement during normal operations

- Ensures flange integrity until the next shutdown opportunity

- Validated by FEA to perform at 1.5 times rated line pressure with all flange bolts removed

Industry Challenges

- Corrosion of piping systems

- Flange and weld failures

- Safety risks

- Costly repair works

- Shutdowns – Penalties

- Loss of containment – Loss of production

Our Clients:

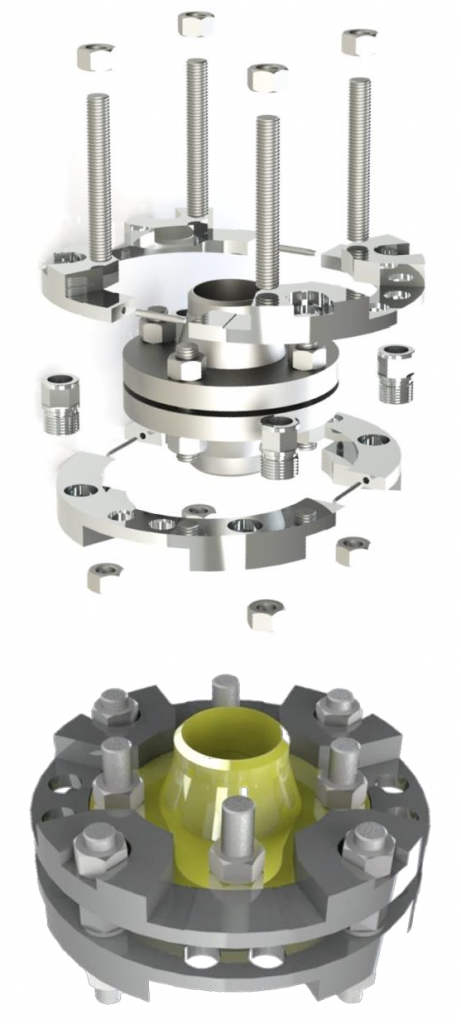

BoltEx® – Bolt Exchange Clamp

BoltEx® can be left installed as a preventative measure on defected flanges with bolts that are impossible to retrieve/replace, extending flange lifetime. Corroded bolts can be replaced immediately in accordance with ASME PCC-2 (Hot Bolting).

Key benefits:

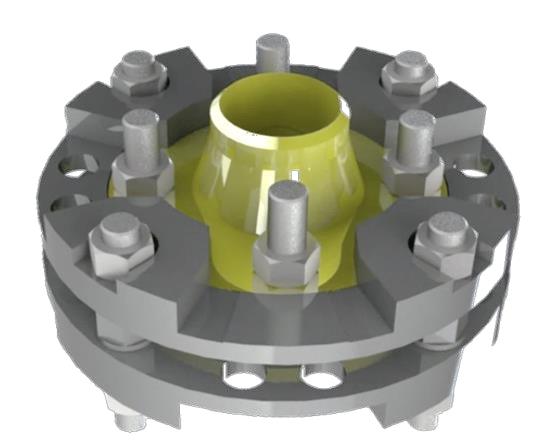

Quick and safe to install

- 1-2 installers

- Available at short notice

- Optimised weight for ease of use

- No damage or disturbance to gasket

Compact and reusable

- Countersunk bolts in one side for limited access applications

- Open design allows access to the nut splitter for removing corroded flange bolts

- Designed for fast and efficient installation and handling

- Easy to remove and reinstall multiple times

- Space-efficient storage and transportation

Cost effective

- Eliminates the need for plant shutdown

- Extends asset lifetime and reduces maintenance costs

Innovative Gasket Protection System (GPS)

- GPS prevents over-compression or release of sealing pressure of flange gasket

- BoltEx® bolts are pre-loaded against the GPS with an equal tension to the flange bolts; compression load on the gasket is therefore maintained as the flange bolts are removed

- In the case of bolt failure BoltEx® will safely take the load preserving joint integrity