Screen Saver Valve™

The Screen Saver Valve is an innovative solution developed to maintain well integrity during completion operations, specifically designed to prevent debris and contaminated wellbore fluids from entering the completion string. Originally developed in collaboration with Det Norske Oljeselskap for the Ivar Aasen development, this valve plays a crucial role in safeguarding sand screens and other downhole equipment from damage caused by unwanted particles and fluids.

Key features

- Prevents debris and fluid entry

- Maintains pressure overbalance

- Adjustable opening pressure

- Metal-to-metal gas-tight seal

- Erosion-resistant construction

- Available in various sizes

Swivel

In the oil and gas industry, a swivel is a mechanical device that allows rotational movement between two connected pieces of equipment while maintaining a pressure-tight seal for fluids (oil, gas, drilling mud, etc.). It’s used in drilling and production operations where equipment needs to rotate but fluids must still be pumped under high pressure without leaks.

- Extended Reach Wells

- Sand Face Completions

- Long Horizontals

- High Step Our Ratio (›2:1)

- Well Bore Clean Out

- Slotted Liners

- Max. Reservoir Contact (MRC) Wells

- ICD & AICD Wells

- S & J Shaped Wells

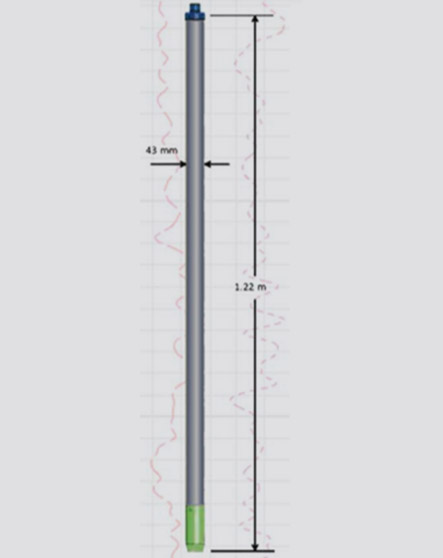

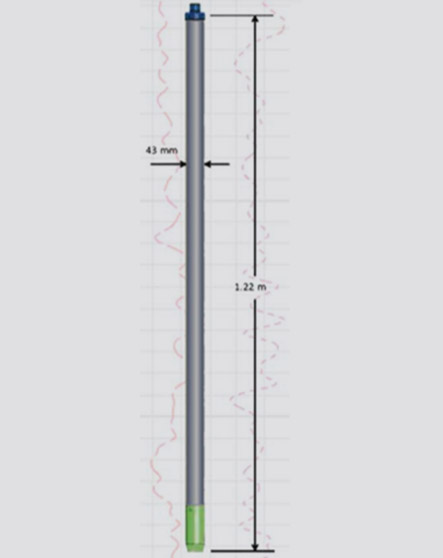

Indexing Sub

The Indexing Sub is a specialized tool engineered to enable controlled rotation of casing or liner strings, addressing the challenges of reaching target depth in complex and difficult wellbores. In operations where conventional string rotation is not feasible or might generate excessive torque, the Indexing Sub provides a reliable solution to rotate the casing in stages. This capability is crucial in navigating tight sections of the wellbore, ensuring that the casing string can be successfully installed to the desired depth without the risk of sticking or excessive drag.

Key features

- Controlled rotation for casing strings

- No torque generation on set-down

- Suitable for cemented or un-cemented casings

- Helps navigate tight well sections

- Compatible with reamer shoes

- Improves wellbore access

F-1 Cable Clamp™

The F-1 Cable Clamp is engineered to set a new benchmark in the installation of upper completions, offering a significant leap forward in both efficiency and safety. Developed in partnership with AkerBP, this innovative clamp is designed to automate the running of upper completions, reducing the need for rig crew presence in hazardous red zones. The clamp’s quick installation and removal capabilities drastically cut down rig time, transforming what used to be a labor-intensive process into a streamlined operation.

Key features

- Quick installation and removal

- Universal layout for various configurations

- High-strength, durable materials

- Improved HSEQ outcomes

- Compatible with multiple completion solutions

- Reduces red zone exposure

LOGGING WHILE TRIPPING (LWT)

SAFE

- Tools and radioactive sources safely located inside LWT collar during deployment & logging

- Radioactive sources and the LWT tools are fully retrievable

- Full well control including pipe rotation and circulation during entire operation

COST EFFECTIVE

- Significant rig time savings over wireline, pipe conveyed, or shuttle logging – Save 2 rig days, $0.6M)

- Considerably more economic than LWD

- Less LIH BHA Cost – Tools are fully retrievable at any time unlike the LWD tools, saving $0.5M

EFFICIENT & PROVEN

- Allows logging of horizontal and hostile holes

- No extra pipe trip to change BHA for LWT operations

- No hole conditioning required

- Compact equipment and small crew

- More than 600 over jobs worldwide

SIMPLE

- Memory based, battery powered instruments; no wireline required

- Logs acquired through LWT collars during normal pipe trip

1473 COMPENSATED DUAL NEUTRON (CN) & GAMMA RAY (GR) Data Sheet

1481 TRIPLE DETECTOR DENSITY (DEN) Data Sheet

1185 DUAL INDUCTION (DUIN) Data Sheet

LOGGING WHILE TRIPPING (LWT)

SAFE

- Tools and radioactive sources safely located inside LWT collar during deployment & logging

- Radioactive sources and the LWT tools are fully retrievable

- Full well control including pipe rotation and circulation during entire operation

COST EFFECTIVE

- Significant rig time savings over wireline, pipe conveyed, or shuttle logging – Save 2 rig days, $0.6M)

- Considerably more economic than LWD

- Less LIH BHA Cost – Tools are fully retrievable at any time unlike the LWD tools, saving $0.5M

EFFICIENT & PROVEN

- Allows logging of horizontal and hostile holes

- No extra pipe trip to change BHA for LWT operations

- No hole conditioning required

- Compact equipment and small crew

- More than 600 over jobs worldwide

SIMPLE

- Memory based, battery powered instruments; no wireline required

- Logs acquired through LWT collars during normal pipe trip

1473 COMPENSATED DUAL NEUTRON (CN) & GAMMA RAY (GR) Data Sheet

1481 TRIPLE DETECTOR DENSITY (DEN) Data Sheet

1185 DUAL INDUCTION (DUIN) Data Sheet