EFTECH Energy Solutions (formerly known as Eftech Drilling Solutions) is a proud partner of Deep Casing Tools in Asia Pacific region. Partnering with this UK-based provider of downhole technology solutions will allow Eftech Energy Solutions (formerly known as Eftech Drilling Solutions) to rapidly respond to growing customer demand in the region by deploying its suite of well construction and completion tools quickly and safely, whilst delivering a high level of on-the-ground service.

Our Clients:

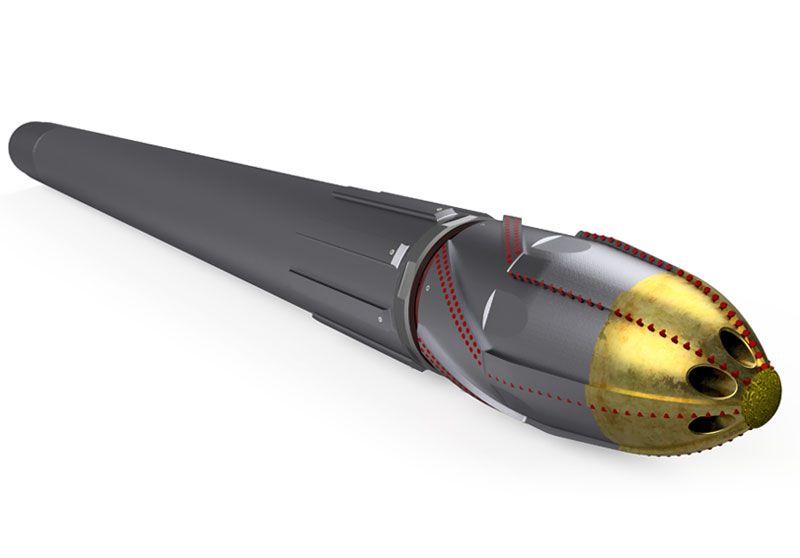

TurboCaser™

TurboCaser™ is a high-speed, turbine-powered casing running system designed to address these challenges. It helps drilling teams to land casings and intermediate liners at target depth in even the most complex wells. The unique drillable turbine can be drilled through in minutes, after normal cementation, in one cost effective operation, allowing the same bottom-hole assembly to immediately drill ahead through the next section.

Key benefits:

- High speed reaming system which lands casing and liners on depth

- No need to rotate the casing or liner reducing potential equipment damage

- Eliminates wiper trips and open hole exposure time

- Cost effect drill through and drill ahead capabilities

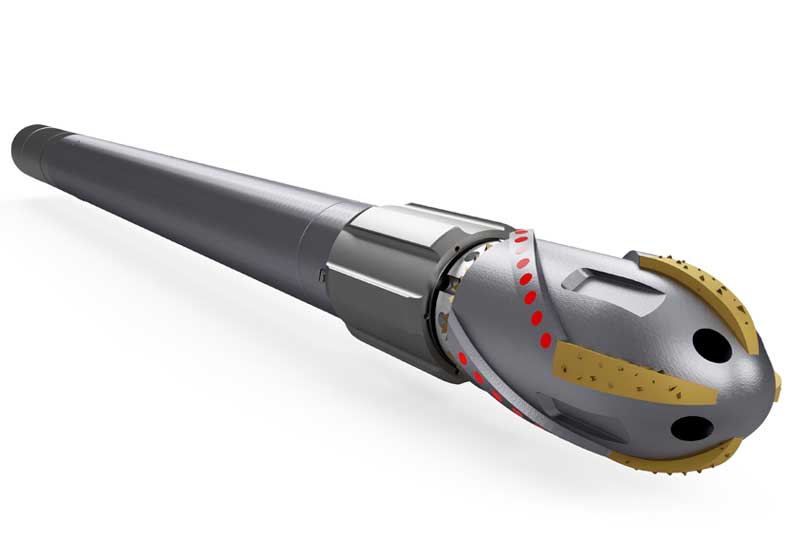

TurboRunner™

TurboRunner™ is a high-speed turbine-powered reaming system that enables completions to land at target depth and access all planned reserves. Its unique design combines high-speed rotational reaming with very low operation pressure, and completely isolates the downhole assembly from the dynamics and vibrations of the reamer shoe, thereby minimising the risk of damage to strings and completions.

Key benefits:

- No need to rotate the completion string, protecting low torque or low strength completion equipment

- Eliminates wiper trips

- Can ream through obstructions other tools can’t

- 75% faster than conventional technology

- Reduces completion running cost by up to 70%

TD Pilot™

TD Pilot™ delivers high-speed reaming to land strings at target depth. Using a unique turbine design, it delivers power to the reamer without any rotation at the surface. Its cost-effective design combines high RPM and torque with low circulating pressures. It is particularly effective in challenging wells, where removing the risk of reactive torque and pressure spikes helps to protect completions and equipment.

Key benefits:

- Reduce well construction costs

- Create reliable connections

- Reduce wiper trips

- Minimise Equivalent Circulating

- Density with low flow rate

- Reach target depth

- Maximise return on investment

- Cost effective offering

MechLOK Drill Pipe Swivel™

MechLOK Drill Pipe Swivel™ is the world’s first mechanically lockable Drill Pipe Swivel. It allows the drill pipe to be rotated independently of the work-string resulting in reduced drag, redistributed friction and mitigation of helical buckling. This, in turn, allows increased weight at the tool to help push the liner string into the well to target depth. This unique tool can be locked at any time, removes any hydraulic concerns, and also reduces the risk of injury during completions, as less manpower is required on the rig floor.

Key benefits:

- Reduce well construction costs

- Create reliable connections

- Reduce wiper trips

- Minimise Equivalent Circulating

- Density with low flow rate

- Reach target depth

- Maximise return on investment

- Cost effective offering